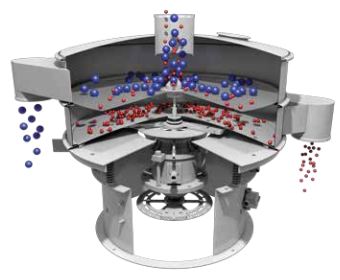

Round Classic Separator

The SWECO Classic Separator offers great value, quick delivery, and the performance you are accustomed to receiving from SWECO brand equipment. Available in 30-, 48-, and 60-inch diameter models, the Classic features a rugged, proven design backed by SWECO and the industry’s most experienced sales engineers.

The SWECO Classic Separator offers great value, quick delivery, and the performance you are accustomed to receiving from SWECO brand equipment. Available in 30-, 48-, and 60-inch diameter models, the Classic features a rugged, proven design backed by SWECO and the industry’s most experienced sales engineers.

Classic Separator No-Tools Features and More...

Features of the Classic Separator include a 12 month motor warranty, no-tools vibration adjustment, no-tools screen center tie-downs, easily accessible motor lubrication points and a hinged base door for easy weight access.

In Stock, Quick Delivery

The Classic separator has been optimally designed to support a wide range of basic separations. With drives and frames in stock, the Classic can be delivered in approximately two weeks or less, and because it is offered in standard configurations, a significant cost-savings has been realized and passed on to the customer. The SWECO Classic – a straightforward, better investment.

IN-STOCK. YOUR APPLICATION SOLUTION IN THREE EASY STEPS.

1. CONFIGURE

SWECO engineers will analyze application requirements and select optimal components for your needs.

: : Separating Solids from Solids (Sifting, De-Dusting, Classifying)

: : Separating Solids from Liquids (Dewatering, Clarifying, Liquid Scalping)

: : Rates Up to 70 tons/hr and 2,000 gallons/minute – Greater Capacity

: : Stainless Steel Product Contact

: : Separating Solids from Liquids (Dewatering, Clarifying, Liquid Scalping)

: : Rates Up to 70 tons/hr and 2,000 gallons/minute – Greater Capacity

: : Stainless Steel Product Contact

2. DELIVERY & STARTUP

AVAILABLE ON DEMAND. Startup assistance, training and safety review.

: : On-Site Startup Services to On-going Maintenance

3. SERVICE AFTER THE SALE

SWECO service engineers are committed to supporting you

: : Long Machine Life, Low Maintenance, Long Screen Life

: : On Demand Customer Care with Available Inventory & Rapid Delivery

: : On Demand Customer Care with Available Inventory & Rapid Delivery

INDUSTRY ADVANTAGE

INDUSTRY ADVANTAGE

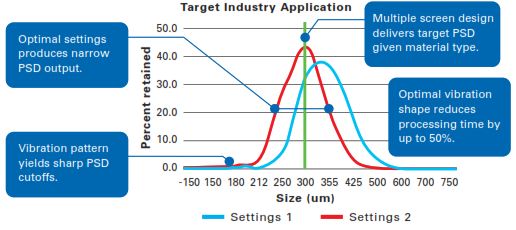

Your process and material separation needs are unique. Our vast application experience, backed by laboratory testing, guarantees outstanding results.

: : Vibration pattern selection --> efficient separation

: : Settings optimization --> maintain quality throughput at high and consistent processing rate

: : Screen design -->configured for enhanced life and higher quality separation

: : Deck / scalping configuration to meet volume requirements

: : Optimizing motion and efficiency for your materials and application needs

: : Vibration pattern selection --> efficient separation

: : Settings optimization --> maintain quality throughput at high and consistent processing rate

: : Screen design -->configured for enhanced life and higher quality separation

: : Deck / scalping configuration to meet volume requirements

: : Optimizing motion and efficiency for your materials and application needs

LET’S GET STARTED MAXIMIZING YOUR INVESTMENT TOOLS AVAILABLE TO TARGET YOUR NEEDS:

With a little data we will develop a tailored proposal.

: : What separation application(s) need a new or better solution?

: : What are your separation process requirements?

: : What’s your timing?

: : What separation application(s) need a new or better solution?

: : What are your separation process requirements?

: : What’s your timing?

No Obligation Feasibility Test.

Free of charge, SWECO ® will conduct feasibility on your sample. Report comprises of:

: : Sieve Analysis or Particle Size Analysis of your materials before and after processing.

: : Scaling analysis for your application.

Performance Standards: : Following Lab Test, SWECO can confirm performance and expected capacity.

Investment Analysis – competitively priced, plus:

: : SWECO Warranty

: : Engineering Support

: : Service

: : After sale support (delivery, setup, training)

Free of charge, SWECO ® will conduct feasibility on your sample. Report comprises of:

: : Sieve Analysis or Particle Size Analysis of your materials before and after processing.

: : Scaling analysis for your application.

Performance Standards: : Following Lab Test, SWECO can confirm performance and expected capacity.

Investment Analysis – competitively priced, plus:

: : SWECO Warranty

: : Engineering Support

: : Service

: : After sale support (delivery, setup, training)

SUPERIOR SCREENING SOLUTIONS

SWECO offers the widest variety of screen solutions to meet any separation challenge. From spot welded screens to our patented Supertaut® Plus and Fusion™ screens, SWECO can fully validate each screen to ensure highest quality. Whatever your screening needs – SWECO is the industry standard.

AUTHENTIC SWECO AFTERMARKET PARTS

SWECO separator aftermarket parts are made to tough, precise standards. Careful materials selection, rigorous quality control and unsurpassed manufacturing methods assure correct fit, superior wear resistance and longer service life for everything from covers to motors.

Look to SWECO for authentic aftermarket products for your SWECO separator.

Look to SWECO for authentic aftermarket products for your SWECO separator.